Ai In Aircraft Maintenance - Today, 85 years after its founding, Bell Flight is still positioned on the leading edge of aviation through its development of tiltrotor aircraft. Owing to their versatility—combining the vertical-lift benefits of helicopters and the speed of fixed-wing planes—the US Department of Defense has fielded tiltrotor aircraft and is evaluating further application as the US Army prepares to replace the Black Hawk.

"The aviation industry has started to exploit the potential of machine learning algorithms on non-safety critical applications," adds EUROCONTROL head of infrastructure division Paul Bosman. "Recently, significant effort has been put on adapting the current certification framework to the specific characteristics of AI applications.

Ai In Aircraft Maintenance

With AI, the industry's focus on cybersecurity has also increased.” Within the group I manage in Bell Flight's Future Vertical Lift program, called Digital Systems, we have a team focused on using aircraft sensor data to fundamentally change how the US military keeps its aircraft fleet at maximum readiness.

Flight Health Checks And Maintenance

From the perspective that counts the most—that of military leaders sending aircraft with soldiers into forward operating areas—readiness means that when the chips are down, the equipment will perform. Anything else puts the mission and lives at risk.

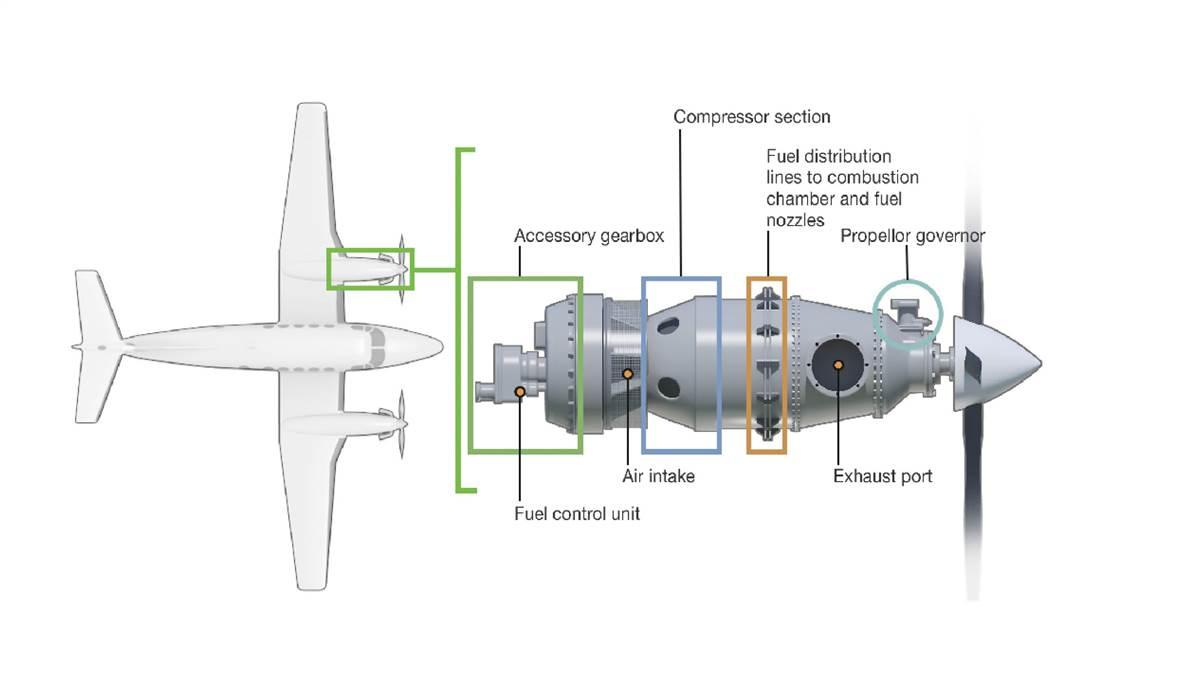

Recently Rolls Royce (premium manufacturer of aircraft engines) has partnered with Azure IoT Solutions to find and develop the power of AI and IoT to accumulate data and find the best predictive maintenance. IoT devices with sensors are being used in aircraft engines to check the health of the engines and monitor all the components in real-time.

"That data really is the key to our awareness of what's happening in the environment, and what's happening in the broader enterprise, to include at home and the depots and the broader supply system," he said.

The first is 3D Spatial Mapping. By streaming raw camera data including RGB color data and, where available, depth data from the device to the GridRaster server we achieve high fidelity 3D scene reconstruction, scene segmentation and 3D object recognition using 3D vision and deep learning-based AI.

Innovative Product Designs

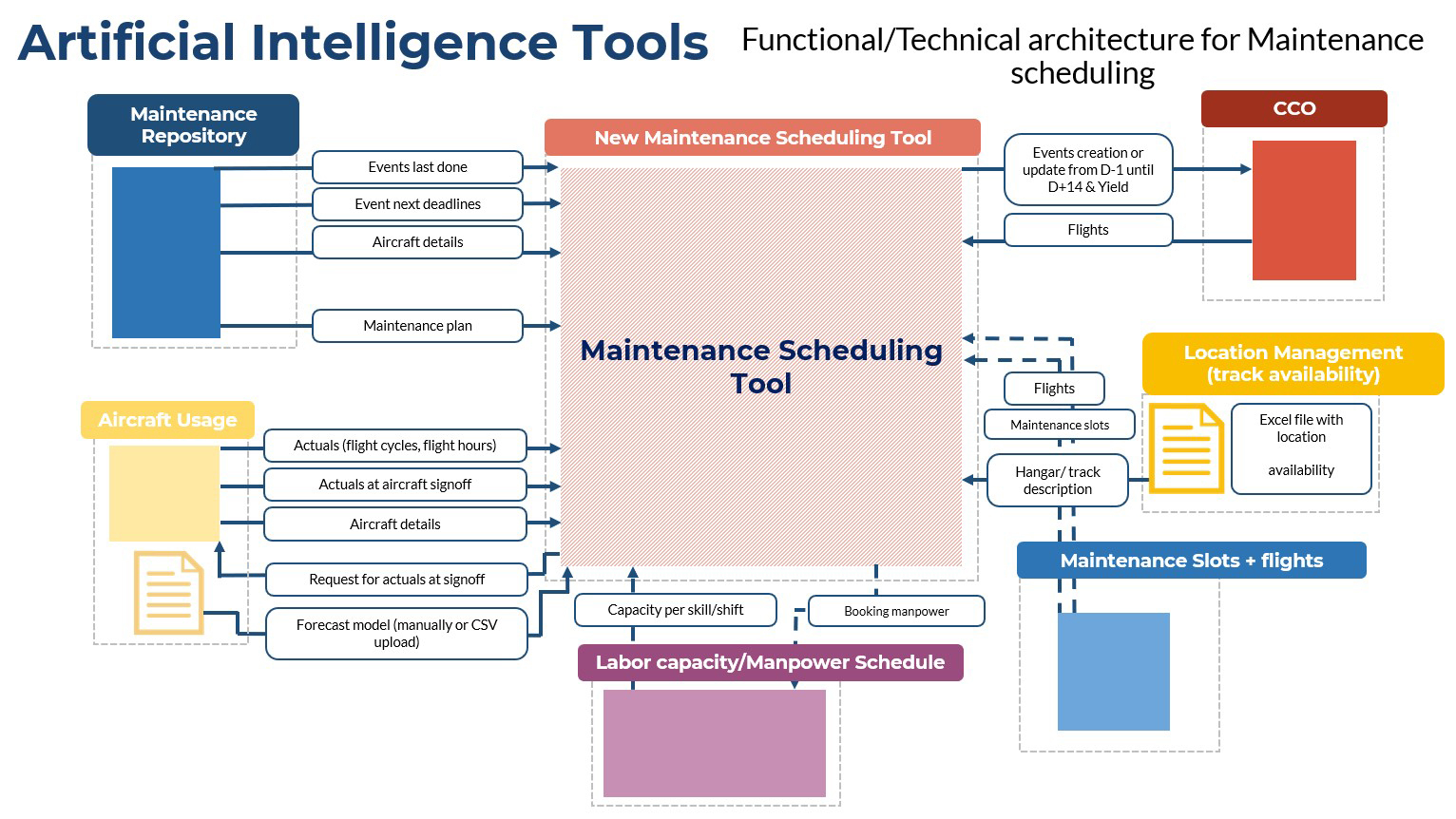

In my previous Nextgov column, I got to interview the general manager of a company that is using artificial intelligence to help the military plan out its maintenance schedules. That program uses AI in a really good way that plays to its strengths, namely its ability to consider thousands of data points, much more than a human ever could, to come up with an action plan for maintenance that maximizes both efficiency and safety.

However, when it comes time to actually perform the maintenance, those tasks must be delegated back to a human. But what happens if those physical tasks are also extremely complicated? Berry said that there are a number of other changes to how the Air Force does logistics that will require future focus, especially the question of how best to preposition supplies in the European and Pacific theaters.

He noted that the Pacific region presents particular problems because of the wide geographic dispersion of allies there. AI is providing new ways to design and develop lighter, more efficient parts for the aerospace industry. Efficient and lighter components are one of the most sought after things in aerospace.

Design algorithms based on AI such as Generative enable engineers to encompass a set of tools and techniques for creating intricate product designs from the data. It allows engineers to view multiple design options and features in less time to find the best designs.

Augmented Reality

This approach helps develop new products with more functionality, making aircraft more sustainable and lighter in weight. AI and augmented reality go hand in hand. With the latest advancements, augmented reality on smart glasses is changing the perspective of aircraft maintenance.

With the technology in testing, now the AR glasses enable mechanics to see hands-free and with interactive 3D wiring diagrams, rather than viewing things on 2D, 20-ft.-long drawings. It also helps users retain the information more efficiently while doing repair work.

According to the developers, this technology already shows a 90% improvement in first-time fixes and a 30% reduction in repair time. Berry noted that the Air Force is "talking to" the Joint Artificial Intelligence Center (JAIC) about best practices and lessons learned as it pushes ahead with its two key predictive maintenance initiatives: "condition-based maintenance plus (CBM+) and "enhanced reliability

centered maintenance (ERCM). AI based technology is rapidly increasing the conditional awareness of military commanders, as well as pilots flying the military aircraft. This technology helps control large laser-based equipment and works as another set of eyes and ears for military pilots.

Ai In Military Aircraft

AI technology driven and regulated by the US defense department is changing the course of action and use of AI in warfare. ERCM, he explained, "is really laying that artificial intelligence and machine learning on top of the information systems that we have, the maintenance information system data, that we have today, and understanding failure rates and understanding mission characteristics of the aircraft and how they

fail," he said. While he said he didn't have the list at his fingertips, Berry said the dozen weapon systems being integrated would come under the ERCM effort by the end of the year. The second part is the 3D AI computer vision.

That is where semantic segmentation and object identification is performed on the reconstructed 3D world, and objects of interest are registered against the database of 3D models and digital twins. The first step will be developing a "federated data foundation and AI-infrastructure" that will grant access to data and enable the creation of an AI aviation partnership.

In addition, the European Aviation High Level Group on AI suggests launching specific aviation/ATM training, reskilling/upskilling programs, change management, a knowledge-based toolbox, and European AI aviation/ATM master classes to share best practices. Awareness and demystification campaigns should also be included.

A New Dimension Of Aircraft Performance

Then, by feeding a wide range of technical manuals into that pool of data, the system was able to tie each failure prediction back to a root cause, down to the part or component level. That made it possible to automatically formulate detailed recommendations for Army aircraft maintainers to follow.

One powerful benefit illustrated by the exercise was how predicting the failure of a relatively low-cost part can avoid the need to replace an entire system—such as an engine—saving well over US$12 million. Panigrahi: The complexity of aircraft wiring for the CV-22 Osprey continues to increase with the fielding and deployment of advanced communications, integrated aircraft survivability systems and aircraft data collection systems.

Maintenance professionals are required to know all variants of the systems. Technicians must maintain extraordinarily complex wiring installations, routing, clamp and abatement placements. Even the slightest mistake comes with extreme safety risk and the potential loss of the aircraft.

John Breeden II is an award-winning journalist and reviewer with over 20 years of experience covering technology. He is the CEO of the Tech Writers Bureau, a group that creates technological thought leadership content for organizations of all sizes.

Predicting Problems Proposing Solutions In Aircraft Life Cycles

Twitter: @LabGuys I was able to interview GridRaster Co-Founder and COO Dijam Panigrahi about bringing technologies like AR and VR, which are most often used in video games like "Pokemon" or "The Witcher" these days, into the practical world of aircraft maintenance.

This involves moving to replace old IT systems with modern capabilities, including cloud storage and data fusion from multiple sensors — whether those be onboard an aircraft such as the F-35 or from a machine doing specific maintenance.

So where does data come in? Even though a piece of military hardware can appear combat ready, there may be parts or components on the verge of failure, and that means risk hiding in plain sight.

The core of our vision is that artificial intelligence (AI) technologies like deep learning can find—in fact predict—those risks before they affect performance and combat readiness. There's a common understanding among all defense contractors that the future will bring a new kind of warfare, one that requires a new generation of weapons that are smarter, more mobile and more autonomous.

Smart Maintenance

But there's also another dimension of weapons performance that we see playing a stealthier role on the battlefield: using advanced analytics to improve readiness. Also critical are the costs of supporting the next generation of combat aircraft, some of which are expected to be in service for more than 50 years.

We recognized that with operations and support accounting for some 70 percent of a fleet's total product life cycle costs, the ability to use data to predict problems has the potential to drastically lower those costs.

Panigrahi: Yes, our platform can support both AR and VR applications. We achieve it by providing a unified API. In VR, we are able to stream experiences at ultra-low latency over the network in very high fidelity, ensuring the realism.

For AR, we also utilize the camera feeds and provide a high precision alignment of virtual objects in the physical world. "I think we need to fundamentally change how we think about prepositioning our assets," he said.

Bonus Ai Leading To Develop Self-Healing Airplanes

"And that really does require partners and allies, in not just prepositioning the material and equipment, but prepositioning capacity and capability — whether that's through operational contracting support or whether that's through things that are actually on the installation that we can take advantage of."

Nextgov: The military version of the maintenance program is still being tested and evaluated, but you have a civilian version being used right now. In that system, maintenance crews are able to see proper wiring configurations rendered on their devices and then line them up over the real thing using onboard cameras to check their work and get assistance when needed.

Has this improved the accuracy of technicians? Predictive analytics by AI work through maintenance data. AI can interpret and organize data from sensors and send the data in a report which can be easily understood. This algorithm also identifies and reports on potential failures in real-time and arranges proper timelines for repairs.

Companies like Airbus are already using and implementing smart AI-based maintenance solutions for their aircraft, based on data from different types of sensors. Bell Flight is the company behind some of the most iconic and groundbreaking aircraft of the 20th century.

Use Of Iot

As depicted in the film, "The Right Stuff," US Air Force test pilot Chuck Yeager was the first to break the sound barrier in the Bell X-1. And Bell Flight also designed and built the world's first commercial helicopter, the military medivac version of which is seen in the opening sequence of the hit TV show M*A*S*H.

On the other hand, EUROCONTROL has acted as leader of the project under the European Aviation High Level Group on AI. The group was formed during EUROCONTROL's inaugural conference on AI that took place in May last year.

Nextgov: Most VR platforms require a headset and lots of other special gear, while AR is able to run on a smartphone or a tablet. But you have found a way to support both technologies through one platform?

"I continue to believe that predictive maintenance is a real game changer for us as an Air Force," he told the Mitchell Institute today. "There's a lot of power in moving unscheduled maintenance into scheduled maintenance, and we're firmly convinced that it will improve our readiness and improve our combat capabilities by doing so."

Fly Ai The Role Of Artificial Intelligence In Aviation

The service has been using CBM+, which involves monitoring platforms on three aircraft: the C-5, the KC-135 and the B-1. "They've been doing it for about 18 to 24 months now, and we're starting to get some real return on what it is that the CBM+ is offering us," he said.

"We have long been a fly-to-fail force," he explained, simply waiting for aircraft to quit working and then trying to fix them by moving parts to wherever the planes were grounded. But today's unpredictable and relatively slow approach to getting fighters and bombers back in the air simply won't be possible in future conflicts, as Russia and China seek to degrade US communications including via cyber attacks and attacks on US bases.

Decades later, AI and its subsets – machine learning and deep learning – are set to influence the future of many sectors, including aviation. Over the last few years, AI has found a wide array of applications in the industry – from ground handling services to airport security and air traffic management (ATM) – and there is now scope for more.

Within this framework, the FLY AI report identified four areas where AI can help tackle current and future challenges. These are airspace capacity, which is rapidly running out in Europe, the climate change crisis, digital transformation and new levels of complexity in the integration of unmanned aircraft in an already overcrowded airspace.

The Importance Of Demystifying Artificial Intelligence

project ai aircraft, free ai aircraft for fsx, world of ai aircraft, ai aircraft x-plane 11, ai aircraft editor, ai aircraft for p3d, ai aircraft fsx

![Pdf] Aircraft Fuel Systems And Their Influence On Stability Margin | Semantic Scholar](https://d3i71xaburhd42.cloudfront.net/7db968837cba7622bb97d20602c656a460374d09/5-Figure10-1.png)

![Dvids - Images - Auab Tests C-17 Globemaster Iii Hot Refueling [Image 19 Of 26]](https://d1ldvf68ux039x.cloudfront.net/thumbs/photos/2104/6607452/2000w_q95.jpg)